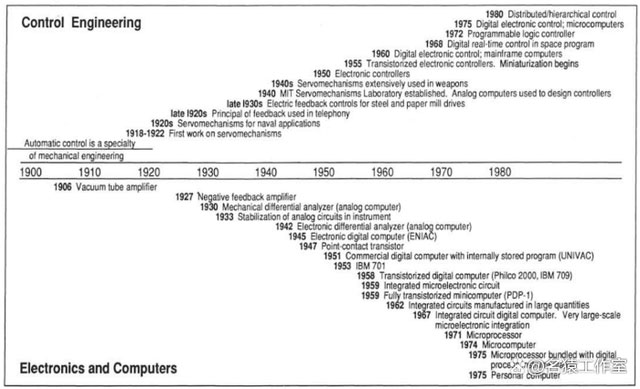

Mar a tha innealan CNC traidiseanta, suidheachadh Còmhnaidh a 'gluasad gu innealan deasga deasga (leithid innealan bhonamadh de inneal-ìne deasg) Miccococontroelpers agus co-phàirtean uidheamachd dealanach eile. Às aonais na leasachaidhean sin, cha bhiodh na h-innealan fòn-làimhe sin comasach, cumhachdach agus co-chòmhnaichte agus co-chòmhnaichte.

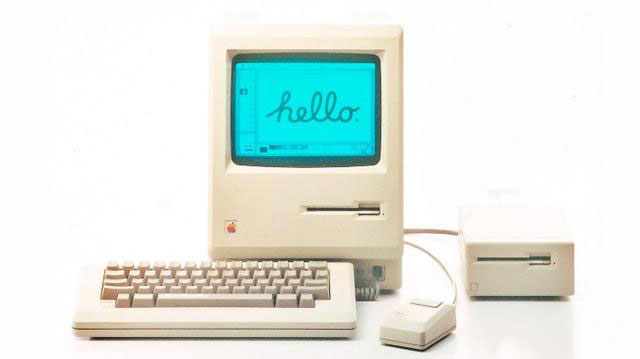

An latha an-diugh a ' choimpiutair pearsanta

The intermediary between computer and CNC machine tool is two basic programs: CAD and cam. Mus dèan sinn sgrùdadh air eachdraidh ghoirid an dà chuid, seo sealladh farsaing.

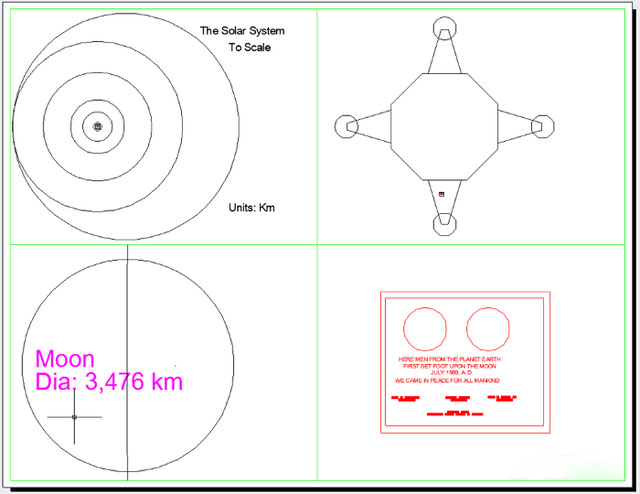

CAD programs support the digital creation, modification, and sharing of 2D or 3D objects. Leigidh am prògram cam leat innealan, stuthan agus suidheachaidhean eile a thaghadh airson obair gearraidh. As an engineer, even if you have completed all the CAD work and know the appearance of the parts you want, the milling machine does not know the size or shape of the milling cutter you want to use, or the details of your material size or seòrsa.

Bidh am prògram cam a’ cleachdadh a’ mhodail a chruthaich an t-Innleadair ann an CAD gus obrachadh a-mach gluasad an inneil anns an stuth. Bidh na h-àireamhachadh gluasad sin, ris an canar slighean innealan, air an gineadh gu fèin-ghluasadach leis a’ phrògram cam gus an èifeachd as motha a choileanadh. Faodaidh cuid de phrògraman cam ùr-nodha atharrais air an sgrion mar a bhios an inneal a’ cleachdadh an inneal as fheàrr leat airson stuthan a ghearradh. An àite a bhith a’ gearradh dheuchainnean air fìor innealan inneal a-rithist is a-rithist, faodaidh e caitheamh innealan, ùine giollachd agus caitheamh stuthan a shàbhaladh.

Timcheall 1967, fhuair Pàdraig J. Hanattty e fhèin don dealbhadh coimpiutaichte le taic bho choimpiutairean Tiomnadh aonaichte (CATED).

Is fhiach a bhith mothachail gu bheil Autocad, air a chuir air bhog le Autodesk ann an 1982, a 'chiad phrògram cad 2D airson coimpiutairean pearsanta seach coimpiutairean pearsanta seach coimpiutairean pearsanta. Ann an 1994, rinn Autocad R13 am prògram co-chòrdail ri dealbhadh 3D. Ann an 1995, chaidh Losworworworks a leigeil ma sgaoil le adhbhar cleas a dhèanamh nas fhasa do luchd-èisteachd nas fharsainge, agus an uairsin chaidh innleadair aughsraiche a chuir air bhog ann an 1999, a thàinig nas intuitive.

It is impossible to talk about the development of CNC machines without paying tribute to the software creators who are committed to reducing the entry threshold of digital design and making it applicable to all skill levels. An-dràsta, tha Autodesk fusion 360 aig fìor thoiseach. (compared with similar software such as Mastercam, UGNX and PowerMILL, this powerful cad/cam software has not been opened in China.) it is “the first 3D CAD, cam and CAE tool of its kind, which can connect your entire product development pròiseas gu àrd-ùrlar stèidhichte air sgòthan a tha freagarrach airson PC, Dàtaan Mac agus gluasadach. " Tha an toradh bathar-bog cumhachdach seo an-asgaidh airson oileanaich, luchd-foghlaim, tòiseachadh teisteanasach agus neo-dhreuchdail.

Mar a bha aon de na tùsairean agus sinnsearan de innealan co-inneale CORN, bha Talla Ted Compacte, a stèidhich innealan bùtha-bhùth, na àrd-ollamh de Nuroscience aig Oilthigh Dhiùc. Anns an ùine shaor aige, is toil leis bàtaichean Plywood a dhèanamh. Choimhead e airson inneal a bha furasta Plywood a ghearradh, ach eadhon prìs a bhith a 'cleachdadh innealan bleith CNC aig an àm sin nas àirde na $ 50000. Ann an 1994, sheall e buidheann de dhaoine am muileann compct a dhealbhaich e anns a 'bhùth-obrach aige, agus mar sin a' tòiseachadh air turas na companaidh.

Ann an 2001, stèidhich Institiùd Teicneòlais Massachusetts (MIT) ionad ùr-lann medagan, agus tha an t-ollamh Neil Gersshend. Thathas den bheachd gu bheil Gerdhenfeld mar aon de na stèidhich an fhillte Lab Lib (Ray Obair-labountory). Le taic bho bhith $ 13.755 millean Teicneòlas Fiosrachaidh bhon bhun-stèidh saidheans nàiseanta, thòisich am meadhan bit agus atom (CBA) a 'sireadh lìonra stiùidio pearsanta gus an sluagh a chruthachadh gus innealan saothrachaidh didseatach pearsanta a chruthachadh.

Ron àm sin, ann an 1998, dh 'fhosgail Gersthenfeld cùrsa leis an t-ainm "Mar a nì thu oileanaich teicneòlas gnìomhachais daor gus na dhiofar chùl-raointean a ghabhail a-steach, nam measg ealan, dealbhadh agus ailtireachd. This has become the foundation of the personal digital manufacturing revolution.

One of the projects born of CBA is machines that make (MTM), which focuses on the development of rapid prototypes that can be used in wafer factory laboratories. One of the machines born in this project is the MTM snap desktop CNC milling machine created by students Jonathan ward, Nadya peek and David Mellis in 2011. Using heavy-duty snap HDPE plastic (cut from the kitchen chopping board) on a large shopbot CNC milling machine, this 3-axis milling machine runs on a low-cost Arduino microcontroller, and can accurately mill everything from PCB to foam and wood. Aig an aon àm, tha e air a chuir a-steach air an deasg, so-ghiùlain agus aig prìs ruigsinneach.

Tha MTM Snap a 'coimhead coltach ri dèideag, ach tha e air atharrachadh deasg gu tur.

Ann an spiorad fìor-lab lab, bha an sgioba Snap Motm eadhon a 'roinn am bile stuthan aca gus an urrainn dhut a dhèanamh fhèin.

Bha an sgioba ag obair aig Overelab ann an San Francisco, air a rèiteachadh agus ath-sgrùdadh agus ath-sgrùdadh a dhèanamh air dealbhadh inneal Mìle SNAPLE CRCS, mionaideachd agus furasta a dhèanamh de chleachdadh. Dh 'ainmich iad e eile Aonghas, agus is e sin a bha ann an cuid dhiubh bho na h-innealan sadanm deasg Inneal Milling PCB.

Evolution de thrì ginealaichean de mhuilinn eile

Anns a 'Chèitean, 2013, chuir an sgioba inneal eile co. gu soirbheachail gnìomhachd sluaigh. A month later, in June, shopbot tools launched a campaign (also successful) for a portable CNC machine called handibot, which is designed to be used directly on the work website. The main quality of these two machines is that the accompanying software – otherplan and fabmo – are designed to become intuitive and easy-to-use WYSIWYG programs, respectively, so that a wide audience can use CNC processing. Obviously, as the support of these two projects proves, the community is ready for this type of innovation.

Tha na seòrsaichean innealan inneal CNC a chaidh a ghluasad bho bhùthan-obrach factaraidh gu deasg a’ fàs gu cunbhalach.

The development goal of the Fab laboratory, originally born at MIT, is to popularize powerful but expensive digital manufacturing machines, arm smart minds with tools, and bring their ideas into the physical world. Is e dìreach daoine eòlach air proifeiseantaich roimhe leis na h-innealan sin fhaighinn. Now, the desktop manufacturing revolution is further advancing this approach, from Fab laboratories to personal workshops, by significantly reducing costs while maintaining professional accuracy.

Ùine puist: Iuchar-19-2022